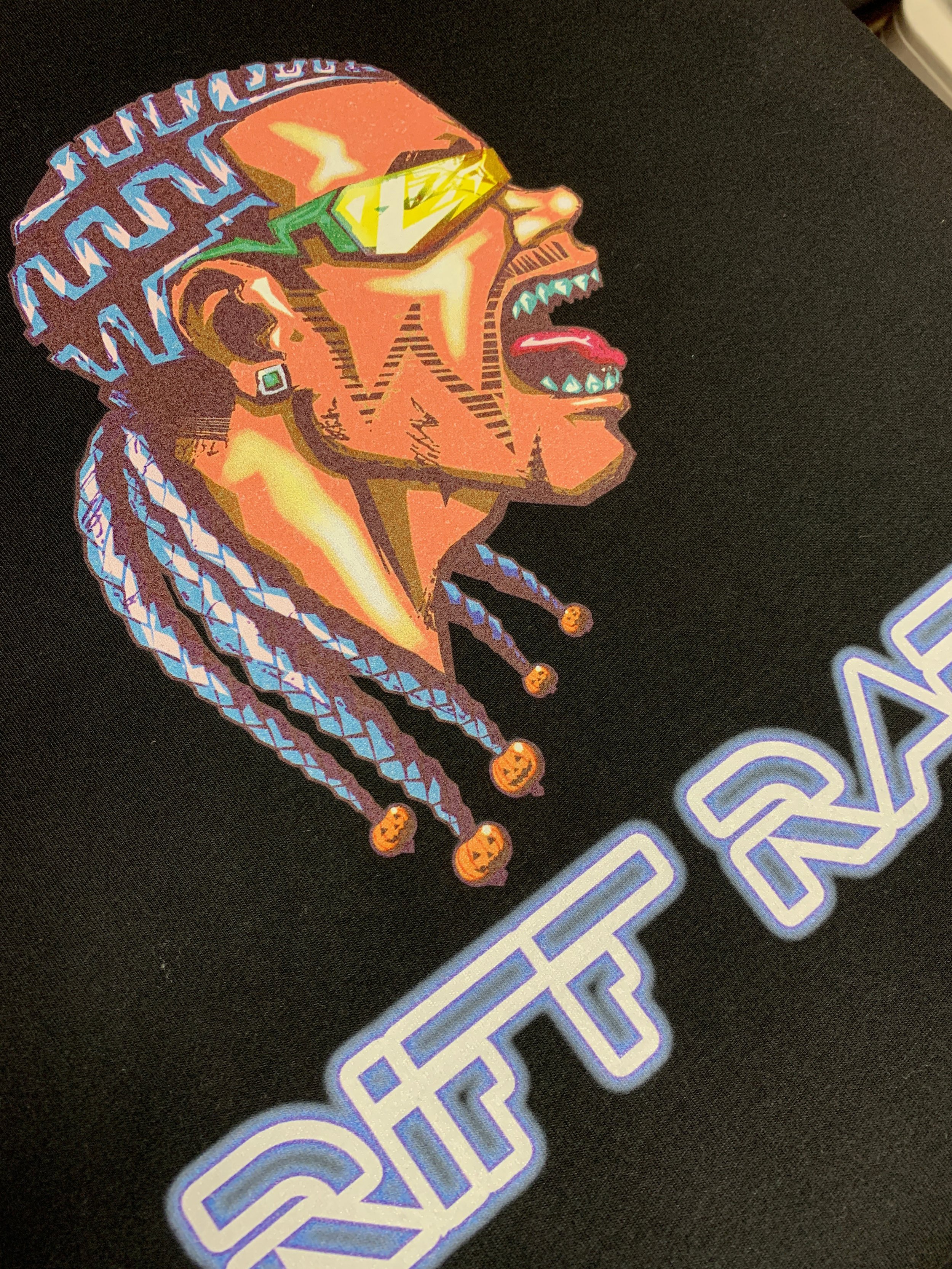

Screen Printing

Using screens to create stencils, ink is then pushed through a different screen for every color, using squeegee. This printing technique is the most traditional and creates high quality, durable prints. Screen Printing is best suited for large quantity jobs with bold graphics or low color counts and non standard print locations such as a sleeve or pocket. Specialty inks can also be used to create desired affects such as metallic, reflective, puff, and more.